- Mobile:+86 18717807449

- Email: lewis@smktek.com

- WhatsApp:+86 18717807449

Commissioning And Maintenance of Air Compressor

PRODUCT CATEGORIES

CONTACT SMK

- Mobile:+86 18717807449

- WhatsApp:+86 18717807449

- Email:lewis@smktek.com

Repair of air compressor, air compresor repair, air compressor maintenance

SMK air compressor engineering technical support team of engineers, can not only provide customers with the daily maintenance of air compressor maintenance services, at the same time can also according to customer needs to provide project solutions, such as: centrifuge overhaul, PC board application Settings, variable frequency energy saving transformation of waste heat recovery, air compressor, air compressor room centralized control and cooling system, etc

Based on the specific situation of customers and the characteristics of each equipment, SMK put ourself in the customer’s mind, from a single part of the parts to the whole compressor , to provide customers with maintenance, repair and transformation services. Repair, replacement, maintenance of impeller rotor, bearing maintenance, repair maintenance, control of the big gear disc repair machine, air compressor maintenance (level 1, level 2 maintenance, three-level maintenance), machine maintenance, dynamic balance, unit overhaul, oil pump, oil pressure failure, motherboard maintenance.

Impeller repair

Welding repairs damage caused by foreign matter and erosion and re-achieves a new aerodynamic configuration. Contents include full size and nondestructive testing, welding, heat treatment, blending, finishing and balancing.

Rotor dynamic balance correction

Rotor repair

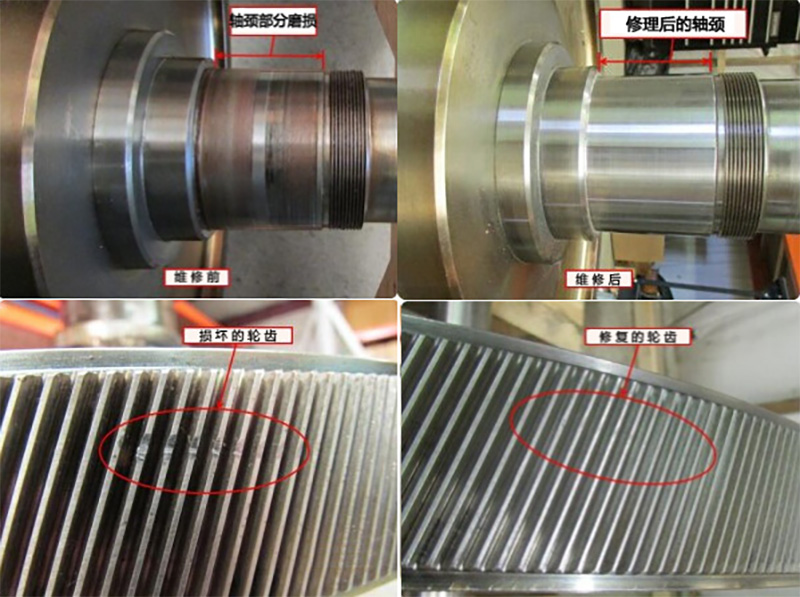

Repair corroded/friction bearing journal, seal journal and blade wheel shaft head. Contents include full size and nondestructive testing, grinding/plating/grinding or high speed flame spraying, finishing and balancing.

Gear repair

Repair corroded/ eroded bearing journal and damaged gear teeth. The contents include full size and nondestructive testing, grinding/ plating/grinding, deployment of damaged teeth and dynamic balancing

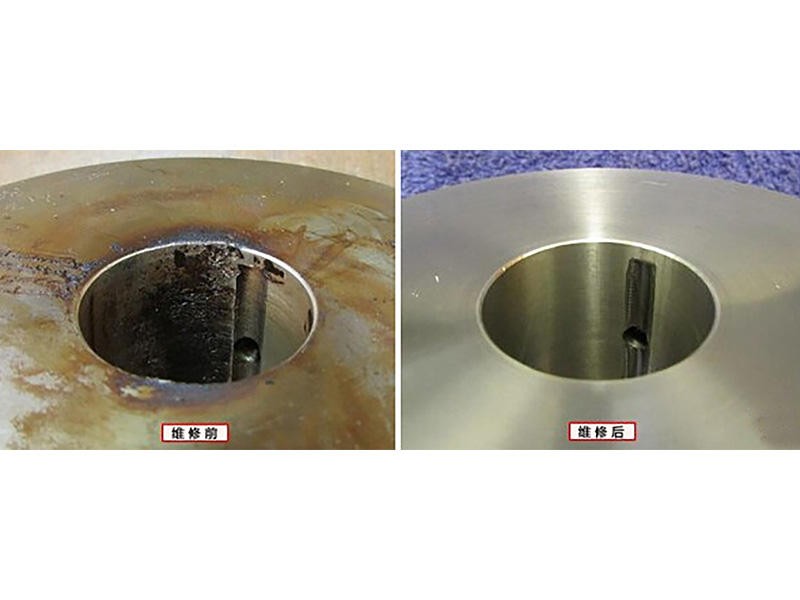

Bearing Repair

Repair tilting tile of rotor bearing and fixed side and fixed side large gear bearing to restore damaged babbitt layer, including removing/ replacing babbitt alloy to make bearing up to new part standard.

Rotor Assembly Repair

Fixed completed rotor assembly. Contents include: disassembly, cleaning, dimensional inspection, nondestructive testing, erosion fusion, replaceable impeller/ rotor/bearing/ seal as required, reassembly, balancing, long-term storage and packing

Whole machine repair

Repair complete air end (gear box part). The contents include disassembly, cleaning, dimensional inspection, nondestructive testing, erosion fusion, replaceable impeller/ rotor/ diffuser/ bearing/ seals/ O-rings/washers/ fasteners/ etc. Reassembly, balancing, painting, long term storage and packing